An atrac® customer received an upgrade from atrac® 1 to atrac® 2 as part of our support program. The changes are extensive and affect almost all technologically relevant software. The upgrade process went smoothly.

The atrac® 2 system offers numerous new and improved features that significantly increase functionality. The customer is pleased with these improvements, which contribute to optimizing their production.

A further patent application for the atrac® system has now been published: DE 10 2023 001 951 describes the automatically adapting local wall thickness control atrac® smart LTC. This wall thickness control compensates for recurring wall thickness deviations from pipe to pipe over the length of the pipe and only requires the online wall thickness measurement on the outlet side. Important: Any reduction in wall thickness deviations can be used to save on the feedstock and in further processing. This is a clear competitive advantage when using the atrac® system.

The new 'problem solver' function of the atrac® system

The latest innovation in production efficiency on the stretch-reducing mill - the new 'problem solver' function of the atrac® system! Thanks to our new technology, common problems such as tube breaks, overloads and speed restrictions are solved. Smooth processes are achieved even in the most challenging scenarios such as particularly thin-walled and thick-walled tubes or very uneven wall thicknesses. With the new atrac® function, dynamic speed control is modified to prevent and minimise these problems. Despite the modification, the same familiar result, uniform wall thickness and low material loss are achieved without compromising performance. Another advantage of the new technology is that motor efficiency is increased and productivity is improved by always being able to utilise the full speed range. A reduction in internal polygon formation can also be achieved. Overall, the new function represents a further significant optimisation step in process automation at the stretch-reducing mill.

The new atrac® 2 is now available.

Extended process model with four adaptation parameters for realistic prediction of the stretch-reduction process. Every mathematical model is based on simplifications of the modeled physical process. Adequate adaptation parameters must be available in order to adapt the model precisely to reality. atrac® 2 is equipped with the necessary number of adaptation parameters. Accordingly, precise precalculation of the process, exactly adjusted process control and good rolling results are possible.

Highest numerical stability. A complex process model requires intelligent numerical solution methods that are fast and reliable. New procedures in atrac® 2 ensure maximum safety in the calculations. Substitute calculations are avoided.

Versatile optimization of the speed curve against overloading, tube rupture and internal polygon formation. The design of the static speed curve determines load distribution, end losses, tube rupture, roll wear and internal polygon formation. With atrac® 2, the speed curve can be adapted to specific problems. Solution schemes that can be combined with each other are offered for this purpose, but a 'free' design of the speed curve is also possible. In each case, the process model determines the physically sensible solution.

Special control variants to reduce the maximum motor load and prevent tube rupture. The dynamic loads during process control play a decisive role in the load distribution and the tensile stress curve, particularly in the phases of end control and dynamic wall thickness control. New control methods in atrac® 2 ensure that the maximum load and maximum tensile stresses are reduced.

Dimension-specific adjustment of the process model. A complete division of the production program into separate, arbitrarily detailed dimension fields makes it possible to adjust calculation and process parameters very precisely. At the same time, the consistency of the parameters always remains in view in the rolling program overview.

Further optimizations in atrac® 2:

Process simulation for each shell for individual optimization.

Improvements to smartTEC and smartLTC for maximum good tube length.

Improved evaluation of measurement data. And much more.

A new, self-learning optimization algorithm improves the tube thickened end control of the atrac® smart control for stretch-reducing mills.

In the case of frequently unavoidable larger wall thickness deviations in the area of the shell ends, the setting of the thickened end control must almost always be actually adapted. In the past, the operator had to perform this task until the automatically adapting thickened end control was introduced. This operation mode carried out the operator's working method, using data storage for the tube sequence and a defined optimization algorithm to achieve a better result that was above all independent of the operator.

In fact, the task of adapting the thickened end control to the current rolling situation is a complex optimization task: by selectively varying several interdependent parameters, an optimum (shortest possible end losses) must be achieved as quickly as possible under specified boundary conditions.

A new improved optimization method solves this task perfectly. For this purpose, the currently valid relation of the parameters (= the formulation of their dependence on each other) is used to execute the variation of several parameters simultaneously, instead of separately and successively, thus minimizing the number of optimization steps. The relation of the parameters is first specified and then automatically optimized with help of practical results. The relation (depending on the rolling situation) is stored and reused together with successful parameter combinations. In this way, a faster, self-learning optimization algorithm for multiple optimization parameters is implemented, another step in the permanent further development of the atrac® system.

Newly developed and already proven in production use is the automatically adapting local wall thickness control smart LTC (Local Thickness Control) as an integral part of the smart control of the atrac® system. Local wall thickness deviations are the changes in the average wall thickness related to the individual tube cross-section over the length of the rolling stock. This is made up of various parts: a trend that is similar from tube to tube, individual deviations that differ from tube to tube, and measurement data errors. Due to the complex composition of these local deviations, it is difficult to adapt a pre-control using the measurement data of the pre-tube based on the measurement data of the rolled tube. A newly developed algorithm now performs this task perfectly and automatically. The smart LTC thus supplements the atrac® smart control with the self-adapting TEC (Thickened End Control) and MTC (Main Thickness Control).

On March 1, 2021, the long-term cooperation between Engels Informatik GmbH and DEHUA GmbH was reorganized. DEHUA GmbH takes over the atrac system and continues business with this product. The cooperation and the personnel base, i.e. expertise and experience, are essentially retained, so that our customers receive the same quality of product and service they are accustomed to. The contact person is now DEHUA GmbH.

In rolling mills, we repeatedly come up against the problem that the operator inputs for the parameters for controlling the crop ends and thus also the result depend strongly on the respective operator.

We re-analysed the problem and chose a completely new approach for our system. That's how atrac® smart control originated.

atrac® smart control can work without any operator intervention. In the course of a rolling process, it constantly compares the results obtained with the set rolling parameters and adapts them, if necessary, until the thickened ends are minimal or the mill has reached the physical limits.

Also taken into account is the protection against material tearing and other critical situations in the rolling mill, therefore: "it will be optimised to the limit".

The best results are stored at the end of the rolling lot and will be reused as the starting parameter for comparable production lots in the future. Then the self-regulation will continue.

Therefore, the problems that have occurred in the past will no longer occur.

The enthusiastic reaction of our customer confirms it: atrac® smart control is a great system, it delivers excellent results!

You can find more information in this short description. For further inquiries, we look forward to your contact.

For good seamless tubes: atrac®. Leading, future proof, reasonably priced.

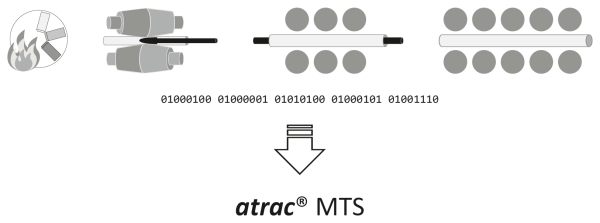

With atrac® MTS you get a better overview of the entire production line, from the furnace to the cooling bed.

To accomplish this, all process data is collected, the rolling material tracked and evaluated via technological process models. Consequently, the entire production line becomes more transparent, and the system automatically notifies of quality-relevant actions. As a result, you achieve higher product quality, safety, and transparency in production.

Learn more about atrac® MTS - download our flyer!

For good seamless tubes: atrac®. Leading, future proof, reasonably priced.

atrac® demonstrably ensures better quality and efficiency in the automated production of seamless tubes.

The goal of the atrac® SRM:Lite app is to further increase the benefits of the atrac® system through flexible access and rapid response.

Useful, secure, and portable - that is the new atrac® SRM:Lite app:

Learn more about atrac® SRM:Lite - download our flyer!

After the first success in Asia, the first atrac® automation system has now started operations in Germany.

Only three months ago, Engels Informatik GmbH received an order from the Bavarian Rohrwerk Maxhütte GmbH for the supply and installation of the automation system atrac® - now the system is already used for production. The advantages of quality and cost of pipe production are achieved.

The high-quality tube manufacturer was convinced by the innovative and low-cost system. Fast delivery and a short commissioning time were the decisive arguments.

The system of the mill manufacturer used until now in the production plant in Sulzbach-Rosenberg has been replaced by the atrac® system in a seamless transition within a few days, without any downtime for the Maxhütte production.

Thanks to the atrac®, the steeped in tradition tube rolling mill will achieve an even better quality of the final product, with optimal utilisation of the raw material and thus will be able to even better maintain its ultimate goal of "seamless quality".

Rohrwerk Maxhütte GmbH belongs to the Max Aicher group of companies, which is wholly-owned by the Aicher family. The company devolops reliable and sustainable solutions since 1952 and reacts to customer requirements in the short term.

Engels Informatik is pleased to be able to enter into a close partnership with the Rohrwerk Maxhütte, which will help to integrate practical insights into steel pipe production into the future system versions.

Engels Informatik GmbH was founded by Thomas Engels in 1995 in Mönchengladbach, Germany. The company's strength lies in providing design, implementation, and operation of secure, highly-available systems that are directly incorporated worldwide into customers' production processes.

atrac® is the product of Engels Informatik GmbH.

Our new flyer "atrac® - automated stretch-reducing of steel tubes" is ready for download!

Among others, the advantages of the atrac® system are:

Learn more - also about our successful atrac® installation in South Korea - download our flyer!

For good seamless tubes: atrac®. Leading, future proof, reasonably priced.

We are pleased to announce that at the beginning of June atrac® has been registered as a German trademark with the German Patent and Trademark Office under registry number 30 2016 104 419.

ILJIN Steel Corporation of South Korea has honoured Engels Informatik GmbH with a purchase order of the atrac® Automation System.

With the atrac® System ILJIN will be able to produce seamless steel tubes of higher quality as well as to improve utilization of both material and energy.

Experience data collected over the time will be stored in the atrac® Archive System and used to assure the best possible quality of the final products.

ILJIN Steel Corporation is a value-creating manufacturer that specialises in steel pipes.

ILJIN Steel was established in 1982 as the subsidiary of the South Korean Total Solution Provider ILJIN. The company built an integrated seamless tube production line in 2011 and is aiming to become a global blue-chip maker of high-value-added special steel pipes.

Engels Informatik is proud to be able to accompany ILJIN Steel in reaching their goal.

Engels Informatik GmbH was founded by Thomas Engels in 1995 in Mönchengladbach, Germany. The company's strength lies in providing design, implementation, and operation of secure, highly-available systems that are directly incorporated worldwide into customers' production processes.

atrac® is the product of Engels Informatik GmbH.

Aiming at reaching the widest possible group of manufacturers of seamless tubes in the world, Engels Informatik established cooperation with DEHUA Handel + Beratung GmbH of Mönchengladbach, Germany. The goal of this collaboration is the representation of atrac® on the Chinese steel market.

We are looking forward to successfully building a new relationship with DEHUA Handel + Beratung as well as to our future joint projects.

If you are interested in acquiring atrac® for a seamless tube mill in the People Republic of China, .

中国市场请按照下列电子邮件联系: & www.dehua-gmbh.com.

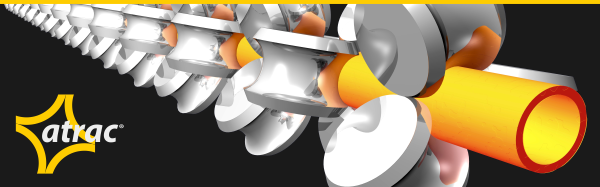

The technological knowledge and many years of experience of the world's leading experts in the automated production of seamless tubes are provided in the four atrac® modules:

Roll speeds, pass design, end losses, optimisation, and loads - for defining set-up data with help of expert knowledge.

more...

Communication, visualisation, messages, supervising, and monitoring - for managing communication and information.

more...

Wall control, end control, adaptations, load control, and fault detection - for dynamically controlling the rolling process.

more...

Data storage, data analysis, visualisation, browsing, and reports - for storing and evaluating experience data.

more...